As people's pursuit of fashion continues to escalate, luggage hardware accessories have gradually become an important element of individuality and taste. Among them, Guangzhou electroplating process is favored by its exquisite technology and excellent texture. Next, let's explore the story behind this unique craft and its charm.

Revealing Guangzhou Plating Process: Why It Makes Hardware Accessories Better

Guangzhou electroplating process is a technology that evenly covers the metal layer on the surface of the substrate through a chemical reaction. Compared with traditional spraying or polishing methods, electroplating can not only significantly improve the gloss of hardware accessories, but also enhance its corrosion resistance and wear resistance. The application of this technology makes each piece of hardware products show a mirror-like delicate and smooth effect, while retaining the high strength characteristics of the material itself.

Selected Material Analysis: What Determines the Excellent Performance of Metal Handles

High-quality hardware accessories cannot be separated from carefully selected basic materials. Under normal circumstances, the high-end luggage hardware produced in Guangzhou is mostly made of stainless steel, aluminum alloy or zinc alloy as raw materials. These materials have good ductility and plasticity, easy to follow-up processing. More importantly, they all have excellent aging resistance and environmental protection properties, ensuring that the final product is safe and durable.

From Design to Finished Product: Explain the Manufacturing Process of Electroplated Hardware Accessories

The birth of a perfect hardware accessories is not achieved overnight, but has experienced a series of complex and rigorous operation links.

First, the designer will draw the first draft drawings according to the market demand, and then handed over to the technicians to reduce the model samples according to the scale. After confirming that it is correct, it enters the formal production stage-first, the blank is cut and polished, and then the preheating and degreasing process is carried out to ensure the surface is clean and smooth; Then there is the core part, namely the electroplating process itself. Under the action of current, ions in a specific solution are deposited to form a dense protective film to wrap the outer contour line of the whole workpiece. Finally, non-conforming products can be packaged and listed in the circulation channels through quality inspection screening.

Fashion trend interpretation: the most popular luggage hardware accessories style

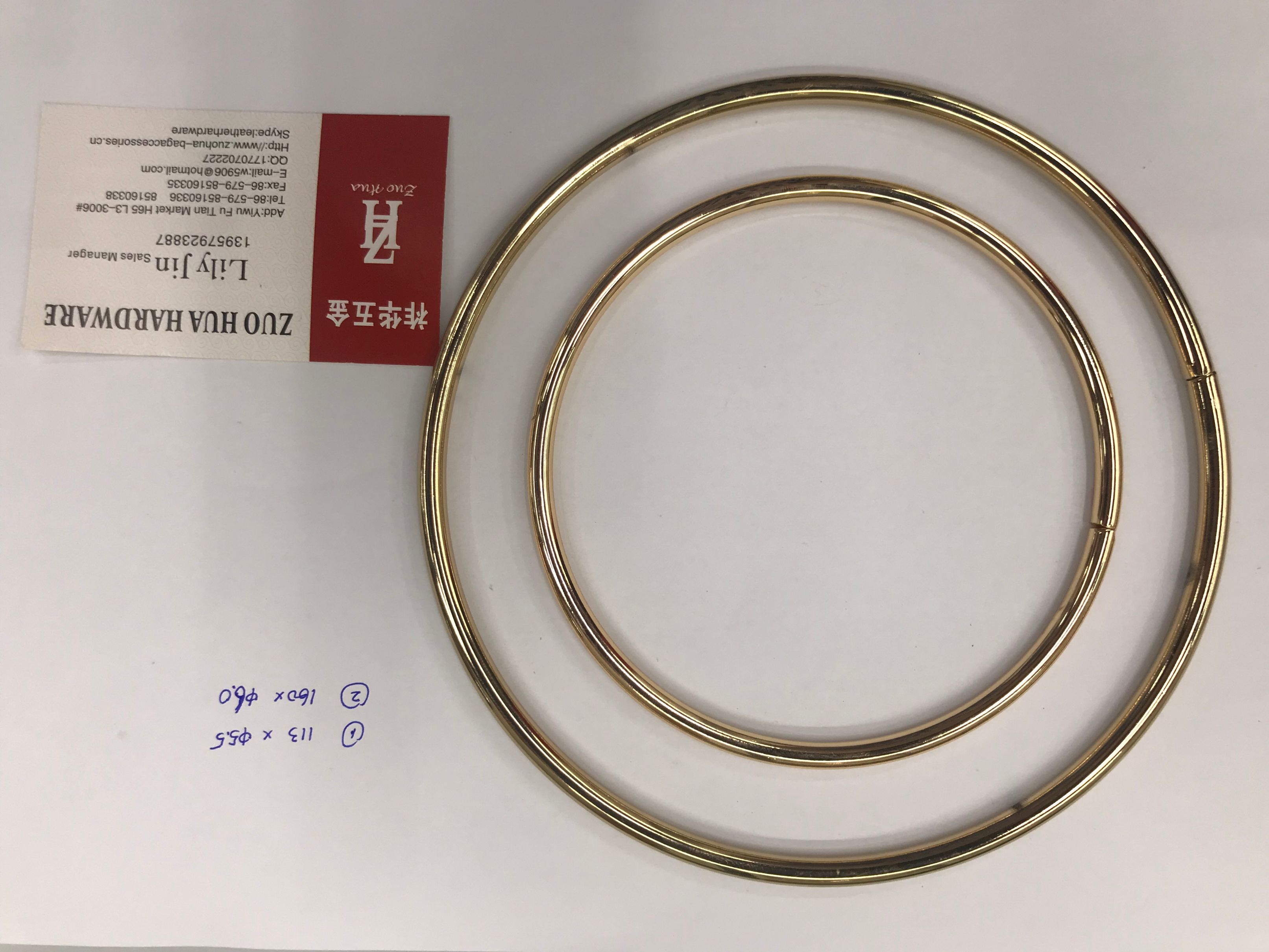

Now on the market popular luggage hardware decoration style is varied, each has its own merits. For example, the brass-tone handle led by the retro trend brings a strong historical charm without losing the beauty of modern simplicity. There are also minimalist admirers who like silvery white matte plating effect, which can better reflect the low-key, luxurious and connotative life attitude concept. No matter what type of design, you can always find the one that fits your personal preferences.

Selection tips: how to choose your own high-end metal handbag handle

the following aspects should be paid attention to in the process of purchasing:

one is to observe whether the appearance quality is intact, including the roundness of corner transition and whether there is virtual welding at the welding place, etc. The second is to weigh the weight, feel the hand feeling is appropriate, so that the portable belt will not feel too burdensome for long-term use; third, asking for specific parameter information such as load-bearing limit value range and other data indicators is helpful to judge the actual applicable conditions.

Intimate advice: Proper care method to extend the life of hardware accessories

in order to keep the beloved luggage hardware accessories in the best condition, please be sure to follow the following maintenance tips:

often wipe with a soft cloth dipped in a small amount of warm water to remove the dust particles accumulated daily; Avoid contact with acid and alkali strong liquid substances to corrode and damage the structural stability of the surface coating; Keep away from high temperature and humid environment to prevent oxidation and rust from affecting the overall appearance.