Explore the origin of high-quality hardware accessories

The luggage hardware industry has a long history, and Guangzhou, as one of China's manufacturing centers, occupies an important position in this field. From the early simple handmade to modern large-scale production, Guangzhou has gradually become a hardware accessories production base with its unique geographical advantages and technological innovation capabilities.

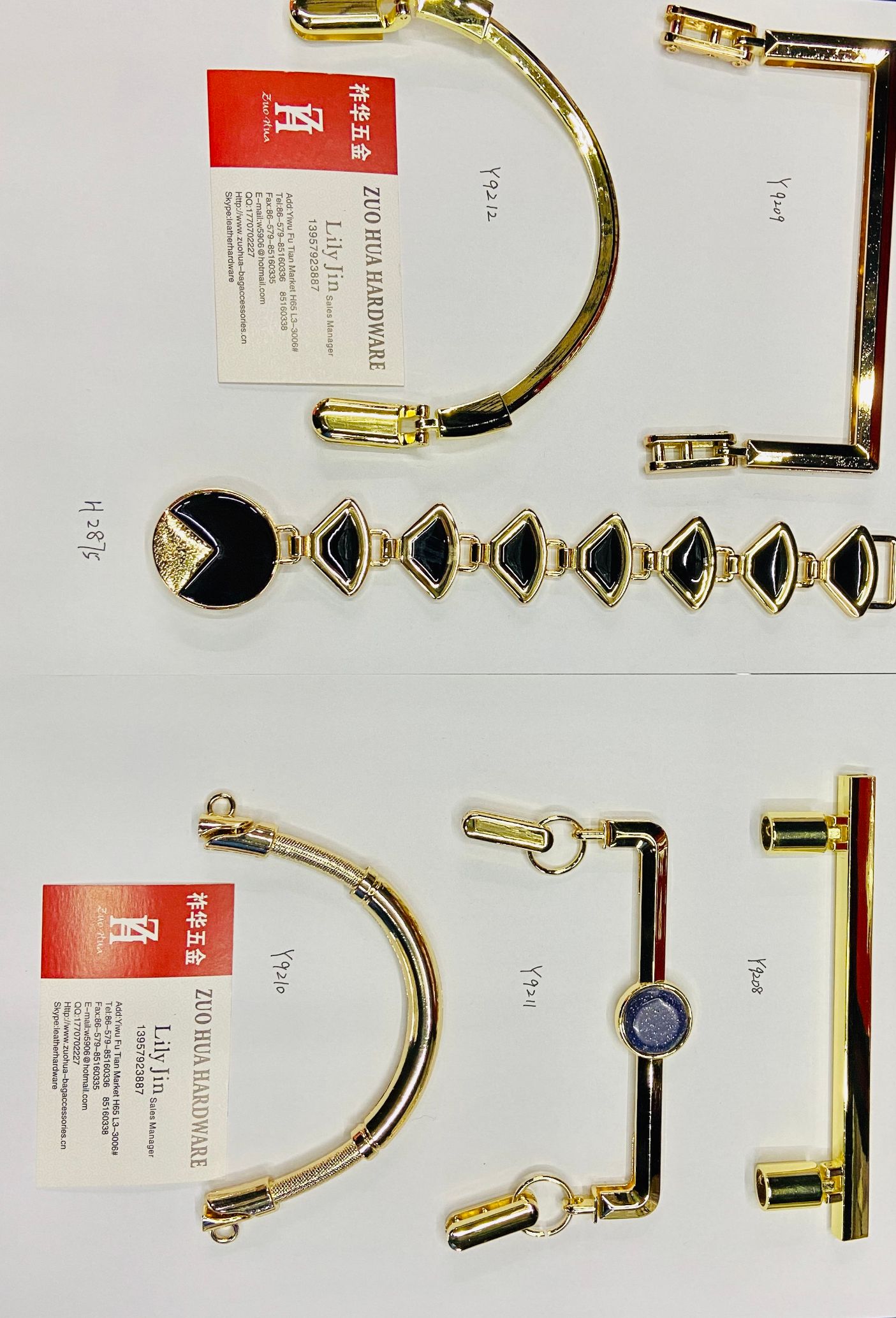

Especially in recent years, with the increasing maturity of electroplating technology, the metal handles produced in Guangzhou have not only been unique in appearance design, but also have been greatly improved in terms of durability and aesthetics. The progress of this process makes every detail exudes high-end quality.

See the real chapter for details: the power of handbag handles

For a perfect handbag, the metal handle is not only a functional component, but also the soul of the whole design concept. Compared with the handle made of plastic or other synthetic materials, the metal products made of high quality steel and precision machining have stronger load-bearing capacity and higher wear resistance.

Not only that, but the different styles also give them their own unique charm. For example, the simple and elegant classic arc type is suitable for business occasions, while the artistic style with complex carving patterns is more suitable for dinner parties or special parties to carry. These differentiated choices allow users to choose the one that suits them best according to their preferences.

Material selection and environmental awareness in parallel

Facing the increasing pressure of social responsibility, many brands have begun to pay attention to the sustainable development of products. This means not only ensuring the quality of the final product, but also considering whether the source of raw materials is green and whether the carbon emissions throughout the life cycle can be effectively controlled.

At present, several main raw materials commonly used in the market, including but not limited to stainless steel, aluminum alloy and even recycled steel, can meet the above requirements. At the same time, researchers are actively exploring the possibility of more new composite materials in an attempt to further reduce the cost of resource consumption while also reducing the risk of environmental pollution.

Customized services meet individual needs

In this era of pursuing uniqueness, it is obvious that the "one-size-fits-all" mass market can no longer fully meet the expectations of all consumers. Therefore, more and more companies have introduced personalized customization solutions to allow customers to participate in product development links to jointly create a truly unique work.

Through advanced computer-aided design software combined with the experience of skilled craftsmen, you can easily achieve various complex surface texture treatments or luxurious decorative effects such as gemstones. In this way, whether you are fond of simple Nordic style or retro court style, you can always find the right one.

Future Trend Outlook: Intelligent Technology Integrates into Hardware Facilities

Looking forward to the near future, we can foresee that the wave of intelligence will sweep the entire luxury accessories field. Imagine if in the future every metal handle can be embedded with a microchip to record the user's behavior and have the function of automatically adjusting temperature and humidity, will it be more surprising?

of course, all this still needs to rely on the joint efforts of interdisciplinary fields to become a reality, but at least some pioneers have taken the first step now. I believe that with the passage of time, this black technology will eventually become standard and enter thousands of households. go!