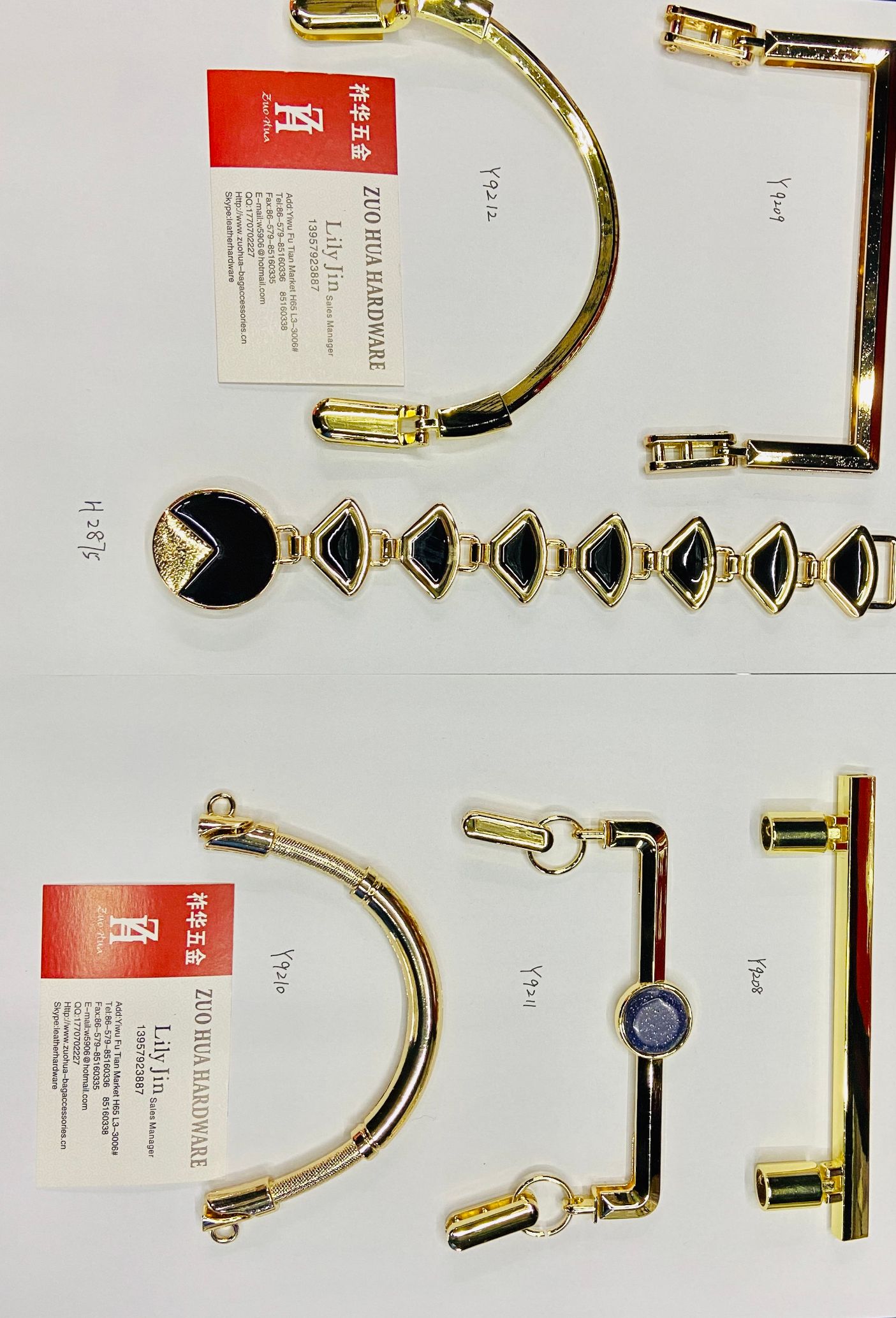

Stylish & Durable Luggage Hardware Accessories – Electroplated Metal Handles for Fashion Bags

Elevate your design with premium electroplated metal handles – where strength meets elegance.

When Details Define Taste: How Luggage Hardware Reshapes the Texture of Fashion Bags

From haute couture runways to bustling city streets, one subtle trend has taken center stage—hardware details that whisper sophistication. No longer just functional components, metal handles have become silent storytellers of quality and intent. Designers are increasingly turning to electroplated metal handles not merely for durability but as a statement of craftsmanship. Behind this global shift lies a quiet revolution in Guangzhou’s manufacturing hubs, where precision engineering meets aesthetic innovation.

Today’s discerning consumers don’t just buy a bag—they invest in its longevity and identity. And increasingly, they’re willing to pay a premium for what some call “invisible luxury”: elements like handbag hardware that aren’t immediately noticed but profoundly felt through use. Electroplated metal handles offer exactly that—a seamless blend of resilience and refinement, elevating even the simplest silhouette into something memorable.

Material matters: zinc alloy outperforms plastic in weight-bearing and wear resistance.

More Than Just a Handle: Deconstructing the Hidden Skeleton of High-End Bags

Beneath every well-structured handbag is an unsung hero—the internal framework supported by robust hardware. Metal handles do more than look good; they bear the load, resist deformation, and ensure structural integrity over years of daily use. This makes them critical anchors in both tote bags and luxury luggage, especially when filled with heavy contents.

The magic behind their endurance lies in advanced electroplating technology. A triple-layer process—starting with acid cleaning, followed by copper-nickel undercoating, and sealed with a protective top layer—creates a surface that resists rust, scratches, and fading. Unlike untreated metals or low-grade plastics, these handles maintain their luster even after prolonged exposure to moisture or friction.

In real-world testing, zinc alloy handles consistently outperform standard plastic counterparts. They withstand higher torque, resist cracking under pressure, and retain shape after repeated stress. For brands aiming at longevity and sustainability, upgrading to electroplated metal isn’t just a design choice—it’s a strategic commitment to quality.

Minimalist matte finishes bring Scandinavian calm to modern handbags.

Style Is Attitude: The Aesthetic Spectrum of Metal Handles in Contemporary Design

Designers today treat metal handles as expressive tools, shaping brand narratives through finish and form. Consider the sleek matte black handle—its understated sheen echoing Nordic minimalism, perfect for clean-lined shoulder bags meant for urban professionals seeking quiet confidence.

Contrast that with high-gloss chrome finishes, which command attention on evening clutches and metallic evening bags. These reflective surfaces catch light like jewelry, transforming a simple accessory into a bold fashion declaration.

Then there’s the revival of antique brass and aged copper tones—inspired by Renaissance artistry—bringing warmth and heritage charm to bohemian satchels and vintage-inspired luggage. As Pantone’s 2024 color forecasts emphasize earthy terracottas and deep emeralds, electroplating labs are already matching these palettes with custom-hued coatings, proving that even hardware can be on-trend.

Precision plating: each layer enhances protection and visual depth.

The Making of Excellence: Inside Guangzhou’s 7-Stage Craftsmanship Journey

True quality begins long before assembly. It starts with strict raw material selection—only RoHS-compliant, eco-friendly zinc alloys enter the production line. From there, precision die-casting ensures dimensional accuracy down to 0.1mm, guaranteeing perfect alignment with bag frames.

The heart of the process unfolds in the plating chamber. After thorough acid washing to remove impurities, each handle receives a foundational copper-nickel coat, enhancing adhesion and corrosion resistance. The final electroplated layer—whether chrome, gold, or custom pigment—is applied with micron-level consistency, creating a mirror-like or softly brushed effect depending on design needs.

Rigorous quality checks follow: salt spray tests simulate years of humidity exposure, while automated machines perform over a million open-close cycles to test fatigue resistance. Only pieces passing all seven stages earn the mark of authenticity.

Designers now prioritize hardware as a key differentiator in competitive markets.

Designer Insights: Why We Spend 30% More on Premium Hardware

We spoke with emerging Chinese bag designers who revealed a surprising truth: customers often compliment the *feel* of a handle before noticing the fabric or stitching. One label reported a 40% increase in repeat purchases after switching to electroplated metal handles—even without changing other design elements.

“It’s about perceived value,” says Lin Mei, founder of a Shenzhen-based accessories brand. “A sturdy, cool-to-the-touch handle signals care in construction.” She also shared a successful case where outdated inventory was revitalized simply by replacing flimsy plastic handles with retro-bronze metal ones—resulting in a 25% price hike and full clearance within weeks.

Upgrade Your Classic Bag: A Styling Lab for Hardware Transformation

Want to breathe new life into an old favorite? Try swapping its handles. Pair a structured square tote with curved double metal grips to add architectural flair. Or contrast a soft bucket bag with angular, industrial-style fittings for striking visual tension. With basic tools and replacement kits, updating hardware takes less than 20 minutes—offering a sustainable way to refresh your wardrobe without waste.

Future-forward: modular, NFC-enabled, and quick-swap handle systems in development.

The Future Touch: Smart Integration and Modular Hardware Trends

The next frontier? Intelligent handles embedded with NFC chips for authentication and anti-theft tracking. Meanwhile, modular designs allow users to click in different styles—matte for work, glossy for night—adapting one bag to multiple lifestyles. Combined with advances in recyclable plating technologies, the vision is clear: hardware that’s not only beautiful and strong but also smart and sustainable.

In a world where fashion meets function, electroplated metal handles are no longer optional extras—they’re essential signatures of excellence.